Stainless Steel Casting Service

At Syncraft Precision, we produce custom industrial casting products that deliver precision and durability across industries such as mining, marine, and agriculture. With a focus on custom marine components for boats and mining equipment for heavy industries, our solutions are built to perform in the most demanding environments.

- Home

- Stainless Steel Casting Service

Stainless Steel Casting Service

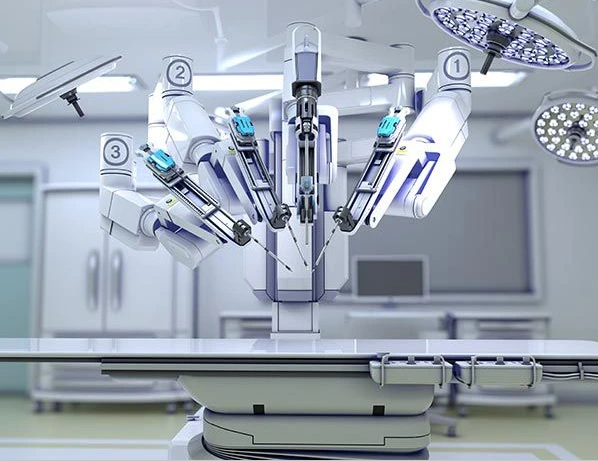

At SynCraft Precision, we specialize in high-quality stainless steel casting solutions tailored to meet the demands of various industries. Our advanced investment casting process ensures precision, durability, and corrosion resistance, making it ideal for aerospace, medical, automotive, and industrial applications.

With cutting-edge technology and strict quality control, we deliver custom stainless steel castings with exceptional surface finishes and complex geometries. Whether you need high-strength components or intricate designs, SynCraft Precision guarantees superior performance and reliability in every cast.

Stainless Steel Casting Process

Once cooled, the ceramic shell is removed, and the raw casting is processed through cutting, grinding, and surface finishing to achieve exact specifications.

Molten stainless steel is poured into the preheated ceramic mold at controlled temperatures to ensure accurate material flow and defect-free casting.

After cooling, the ceramic shell is broken away, and the raw casting undergoes cutting, grinding, and surface finishing to meet precise specifications.

Post Treatments of Stainless Steel Casting

Heat treatment enhances the mechanical properties of stainless steel castings by refining grain structure, relieving internal stresses, and improving strength and toughness. Common methods include annealing, solution treatment, and tempering.

To achieve superior aesthetics and functionality, we offer a range of surface finishing techniques, including sandblasting, polishing, electropolishing, and passivation. These processes enhance corrosion resistance and eliminate imperfections.

Precision machining ensures tight tolerances and smooth surfaces for critical applications. Our rigorous quality control processes, including non-destructive testing (NDT) and dimensional inspections, guarantee that every casting meets industry standards.

Stainless Steel Casting Services

| Alloy Name | Mechanical Properties | Material Characteristics | Application Industry | Example Part |

|---|---|---|---|---|

| 304 | High strength, excellent weldability | Corrosion-resistant, non-magnetic | Food processing, chemical | Valves, kitchen equipment |

| 316 | High tensile strength, excellent toughness | Superior corrosion resistance, especially to chlorides | Marine, pharmaceutical | Pumps, marine fittings |

| 304L | Lower carbon for better welding | Corrosion-resistant, non-magnetic | Welded components, food industry | Pipes, tanks |

| 316L | High tensile strength, improved corrosion resistance | Low carbon, non-magnetic | Medical, marine | Surgical instruments, boat parts |

| 410 | Good hardness, moderate strength | Wear-resistant, magnetic | Cutlery, pumps | Blades, pump shafts |

| 420 | High hardness, good strength | Wear-resistant, magnetic | Cutlery, medical instruments | Scalpels, knives |

| 430 | Good ductility, moderate strength | Magnetic, good formability | Appliances, automotive | Exhaust systems, trims |

| 2205 | High strength, excellent fatigue resistance | Good corrosion resistance, duplex structure | Oil and gas, chemical processing | Pipelines, pressure vessels |

| 17-4 PH | High strength, good hardness | Precipitation-hardened, corrosion-resistant | Aerospace, chemical | Aircraft parts, turbine blades |

| 304H | High strength at elevated temperatures | Corrosion-resistant, non-magnetic | Petrochemical, power generation | Heat exchangers, boilers |

Stainless Steel Casting Samples

Advantages of Stainless Steel Casting

Stainless steel investment casting is a highly efficient and precise manufacturing process that offers several benefits for industries requiring complex, durable, and high-performance components.

- Complex Geometries

- Corrosion & Heat Resistance

- Exceptional Strength & Durability

- Material Versatility & Alloy Options

Stainless Steel Casting Applications

FAQs

Stainless steel casting is a manufacturing process where molten stainless steel is poured into a mold to create precise, durable, and corrosion-resistant components. This process ensures high strength, excellent surface finish, and complex design capabilities.

Stainless steel casting offers superior corrosion resistance, high durability, excellent strength, and precision in intricate designs. It is ideal for industries such as aerospace, automotive, medical, and food processing.

SynCraft Precision offers a variety of stainless steel grades, including 304, 316, 410, and 17-4 PH, each suited for different applications based on strength, corrosion resistance, and temperature resistance requirements.

Stainless steel casting is widely used in industries such as marine, oil & gas, aerospace, medical, automotive, and food processing due to its durability, precision, and resistance to extreme conditions.

Compared to other casting methods, stainless steel casting provides better corrosion resistance, higher strength, and finer detail in complex shapes. It is a preferred choice for applications requiring precision, durability, and long-term reliability.

If you have any further questions or need assistance, feel free to get in touch with us today.

Send Us a Message

Why Choose Us

World class quality is our priority

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Quam adipiscing habitant lacinia odio proin class quisque in lectus nostra nibh

Quam adipiscing habitant lacinia odio proin class quisque in lectus nostra nibh

Quam adipiscing habitant lacinia odio proin class quisque in lectus nostra nibh

Quam adipiscing habitant lacinia odio proin class quisque in lectus nostra nibh