Carbon Steel Casting

At Syncraft Precision, we produce custom industrial casting products that deliver precision and durability across industries such as mining, marine, and agriculture. With a focus on custom marine components for boats and mining equipment for heavy industries, our solutions are built to perform in the most demanding environments.

- Home

- Carbon Steel Casting

Carbon Steel Casting Service

Carbon steel casting is a manufacturing process where molten carbon steel is poured into a mold to form a desired shape. This process offers a high degree of precision and versatility, allowing for the production of complex shapes and large quantities of parts. Carbon steel, known for its strength and durability, is often used in industries such as automotive, construction, and manufacturing for parts that require high tensile strength, wear resistance, and toughness. The casting process ensures that these qualities are maintained while achieving detailed specifications and intricate designs.

At SynCraft Precision, we specialize in carbon steel casting services that combine advanced technologies with superior craftsmanship. Our team uses a variety of casting methods such as sand casting, investment casting, and die casting to produce high-quality carbon steel components. Whether you need small or large-scale production, our processes are tailored to meet your exact requirements, ensuring your parts are both durable and cost-effective.

Carbon Steel Casting Process

The carbon steel casting process begins with the creation of a mold using sand or other materials, forming the desired shape.

Molten metal pouring involves transferring liquid metal into molds to create castings, ensuring precise flow for optimal shaping.

After the molten metal solidifies, the cast component is removed from the mold and allowed to cool.

Post Treatments of Carbon Steel Casting

Machining involves precision cutting, shaping, and finishing of materials to meet exact specifications, ensuring optimal performance and accuracy.

Nitriding or carburizing enhances surface hardness and wear resistance, improving durability without changing the core properties of carbon steel.

Coating and painting protect carbon steel castings from corrosion and wear, enhancing durability, appearance, and resistance to environmental factors.

Carbon Steel Casting Grades

| Grade | Description | Application |

|---|---|---|

| ASTM A216 WCB | General-purpose carbon steel with good weldability and machinability. | Valve bodies, pump housings, fittings |

| ASTM A216 WCC | Higher strength than WCB, suitable for high-pressure applications. | Pressure vessels, piping components |

| ASTM A27 65-35 | Low carbon steel with good toughness and impact resistance. | Construction machinery, brackets |

| ASTM A148 80-50 | High strength and toughness for heavy-duty applications. | Gears, crane components |

| ASTM A216 LCC | Low-temperature carbon steel with good impact resistance. | Cryogenic valves, low-temp piping |

| ASTM A352 LC1 | Low carbon steel for low-temperature service with good ductility. | Pressure vessels, low-temp valves |

| ASTM A352 LC2 | Improved toughness and strength at low temperatures. | Low-temp fittings, flanges |

| ASTM A216 A105 | General-purpose forged carbon steel with good machinability. | Flanges, fittings, valves |

| ASTM A105N | Normalized version of A105 with enhanced mechanical properties. | High-pressure fittings, flanges |

| ASTM A350 LF2 | Low-temp carbon steel with good impact toughness. | Low-temp flanges, piping components |

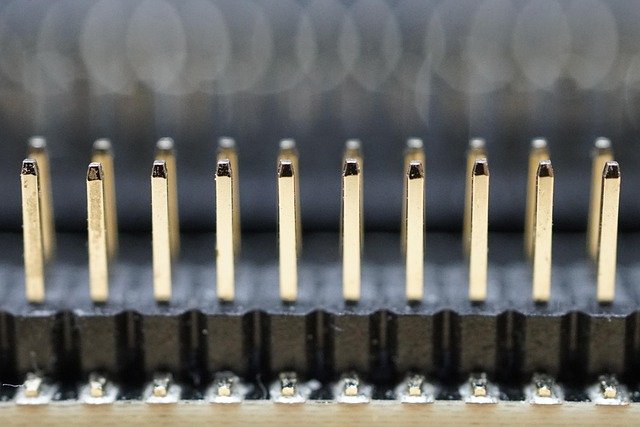

Carbon Steel Casting Samples

Advantages of Carbon Steel Casting

Carbon steel casting offers numerous benefits, making it a preferred choice for a variety of industries.

- Strength and Durability

- Cost-Effectiveness

- Versatility in Applications

- Enhanced Corrosion Resistance

Carbon Steel Casting Applications